Product Introduction:

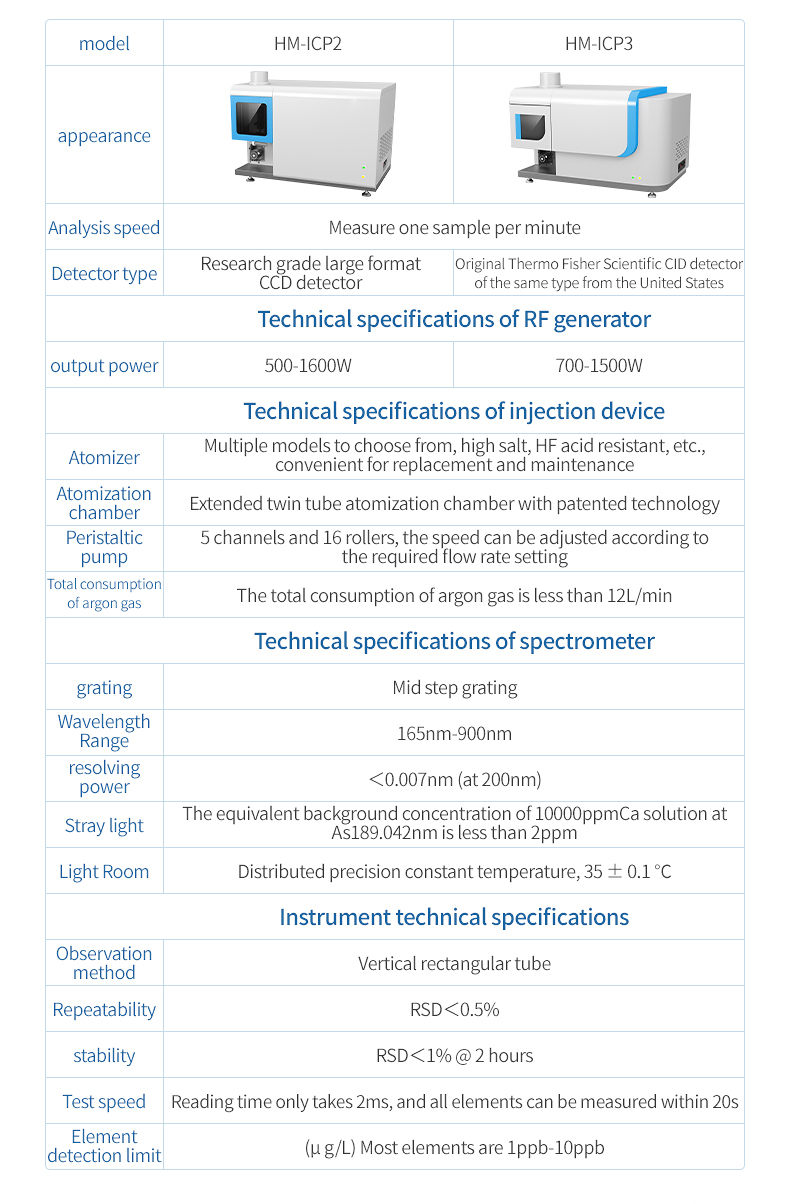

ICP2 atomic emission spectrometer is a new generation ICP-OES product launched by Shandong Hengmei based on years of experience in developing spectral instruments. By utilizing a reliable integrated solid-state RF power supply, a stable constant temperature 2D spectroscopic system, and a research grade refrigeration anti overflow CCD detection system, combined with spectral calibration technology, the operability, flexibility, and reliability of HM-ICP9 are beyond imagination. Daily operation and maintenance are very simple, making it more suitable for experimental operation requirements, achieving miniaturization, intelligentization, and facilitation of the spectrometer.

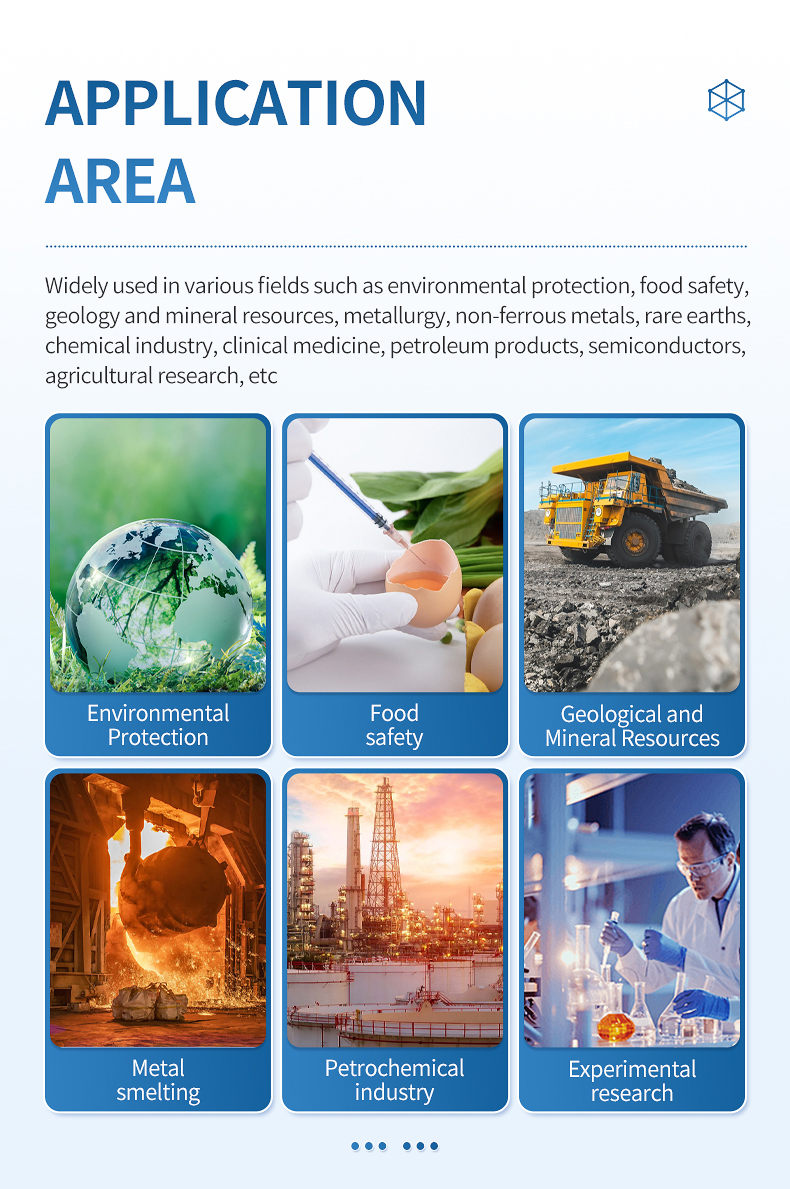

The full spectrum direct reading inductively coupled plasma emission spectrometer is currently the mainstream product for inorganic element analysis. It has the advantages of low spectral interference, good stability, and fast analysis, and is a commonly used method in the field of inorganic element analysis. It can be widely applied in various fields such as environmental protection, food safety, geology and mineral resources, metallurgy, non-ferrous metals, rare earths, chemical industry, clinical medicine, petroleum products, semiconductors, agricultural research, etc. Used for determining the content of constant, trace, and trace elements in different substances, it can be used for qualitative, semi quantitative, and precise quantitative analysis of elements in samples, with a detection limit of up to one billionth.

Performance characteristics:

1. Safe and reliable solid-state RF power supply

The RF power supply used in the instrument has small size, high output efficiency, stable output power, and various safety protection functions such as water, gas, and overload, greatly improving the safety of the instrument and reducing its failure rate.

2. High degree of instrument automation

The automation level of the instrument is high, and all operations except for the power switch are completed by software. Intelligent software that can provide real-time feedback and information prompts for various operations.

3. Fully automatic ignition and matching technology

The software can automatically ignite with one click, and all parameter settings changes are automatically completed. Combined with advanced automatic matching technology, the ignition success rate is high and the operation is simple.

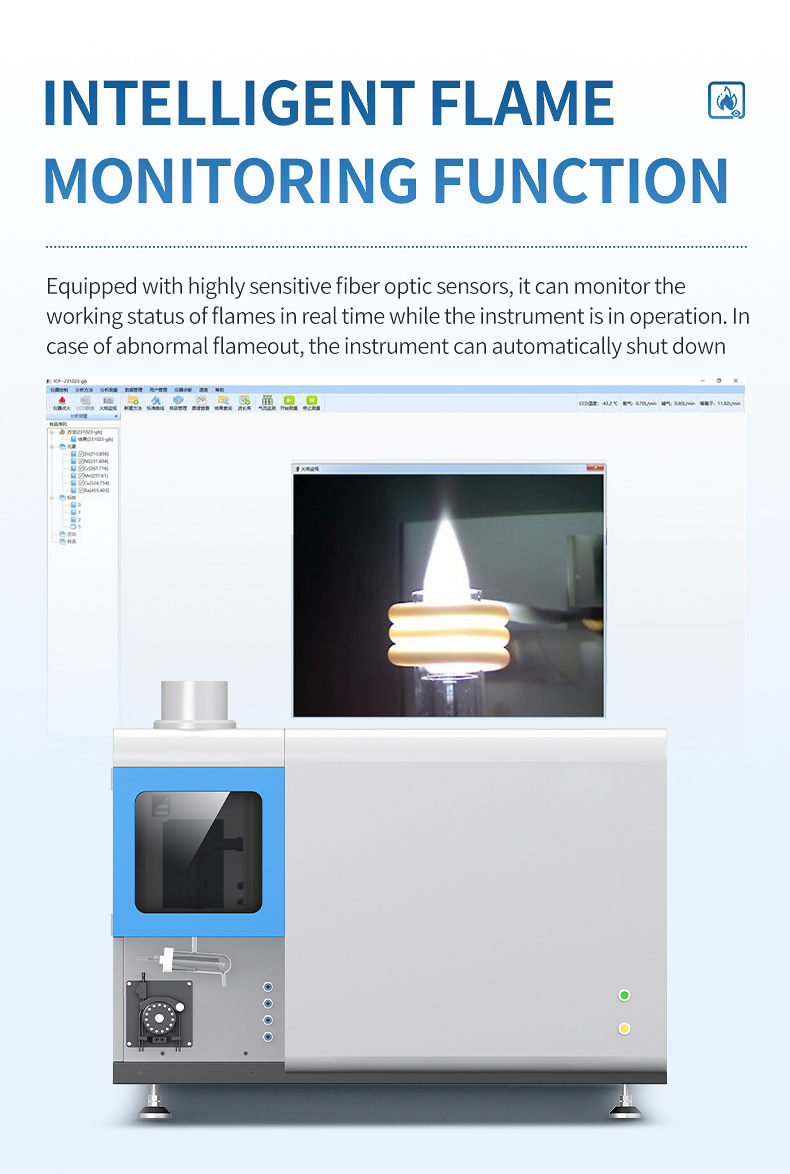

4. Intelligent flame monitoring function

The instrument is equipped with a highly sensitive fiber optic sensor, which can monitor the working condition of the flame in real time while the instrument is in operation. In case of abnormal flameout, the instrument can be automatically turned off.

5. Real time monitoring system for plasma flame

Equipped with a real-time full-color camera system, the operator can view the operation pattern of the plasma in full color in the control software of the instrument, and observe whether the torch tube and the center tube of the torch tube have become dirty and need to be cleaned.

6. Separate injection system

The split design of the fog chamber and torch tube reduces the impact of temperature changes in the combustion chamber on atomization efficiency, allowing for more intuitive observation of real-time injection status. Combined with an extended fog chamber, effective gas-liquid separation is achieved with minimal interference from water vapor.

7. High precision airflow control system

The plasma gas, auxiliary gas, and carrier gas used in the operation of the instrument are all controlled by high-precision mass flow controllers (MFCs), which have continuously adjustable flow rates and high accuracy in outputting airflow, ensuring the accuracy of test data.

8. Peristaltic pump injection device

The peristaltic pump is designed with fifteen rotors and five channels for fully automatic operation, and the rotational speed of the peristaltic pump can be adjusted according to the required flow rate; Can meet the special usage requirements of customers for online sample dilution and online addition of internal standards.

9. Testing speed beyond imagination

The testing speed is once every 20 seconds, and an appropriate integration time can be set for measurement; It is possible to read out the integrated intensity values of all analyzed spectral lines in one exposure; Accurate measurement of nearly 70 elements in a single sample can be achieved within one minute.

10. Research grade large format CCD detector

Adopting a self-developed CCD detection system with millions of pixels; Full coverage in the wavelength range of 160-900nm, with one exposure and simultaneous detection of all elements.

11. Convenient wavelength calibration function

Intelligent automatic wavelength calibration algorithm, the software automatically performs wavelength calibration after startup, greatly saving time and cost in wavelength calibration.

12. Precise spectroscopic system

By using a mid step grating combined with prism cross dispersion spectroscopy, precise optical design can achieve maximum luminous flux and excellent spectral resolution; No moving optical components, ensuring good repeatability and long-term stability; The ultra-low stray light device, combined with optical design, greatly reduces the interference of background light and further lowers the detection limit of the instrument.

13. One second positioning of the torch tube position

By using a torch tube auxiliary installation tool, the concentric circle structure between the torch tube and the coil position can be accurately achieved, while ensuring that there is no displacement in the position and ensuring the stability of the test signal.

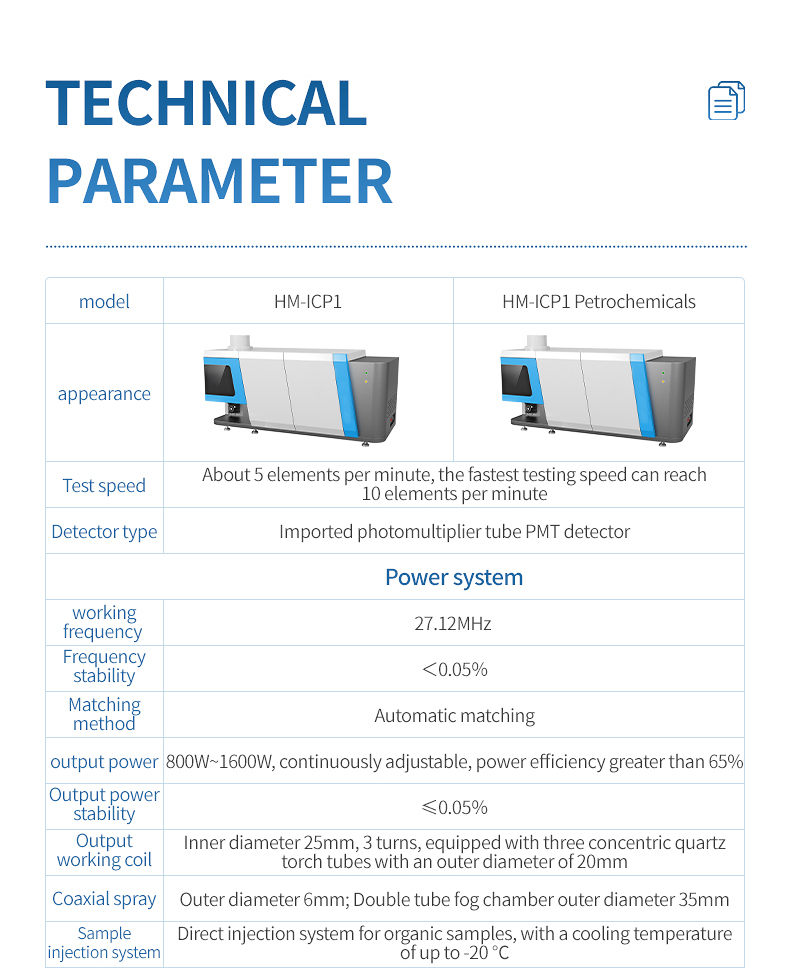

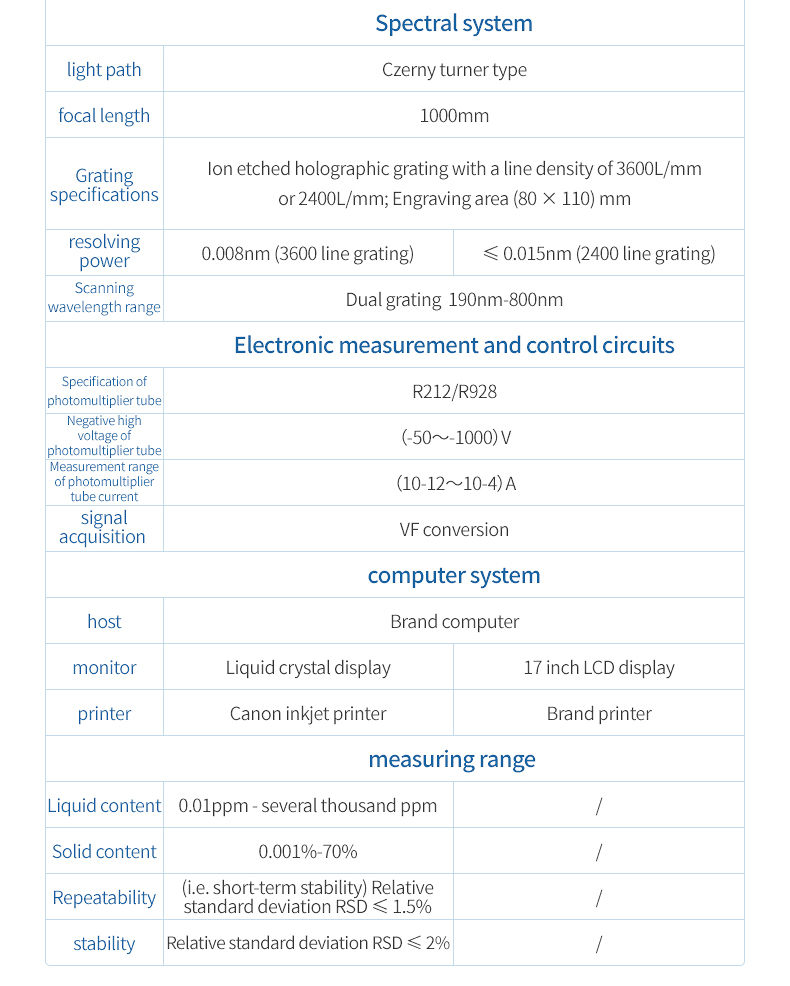

Technical Indicators:

1. Sample injection system

1.1 Extended fog chamber ensures effective reduction of background noise and low memory effect while maintaining high sensitivity.

1.2 High efficiency concentric circle atomizer, with high atomization efficiency, good repeatability, weak memory effect, and can directly self inhale samples.

1.3 Quick disassembly torch tube, combined with independently developed torch tube tooling, can achieve accurate positioning of the torch tube in one second, reducing the impact of position errors caused by replacing the torch tube on testing performance.

The peristaltic pump is designed with 5 channels and 16 rollers for fully automatic operation, and the rotational speed of the peristaltic pump is continuously adjustable. While ensuring stable injection, it can support simultaneous operation of injection, waste removal, online internal standards, and other reagent injection tubes (hydride generators).

The 1.5 split cavity injection system has the torch tube and mist chamber in different spaces, reducing the impact of high temperature in the torch tube on atomization. It can also directly observe the progress of the sample, facilitating real-time elimination of abnormal situations.

1.6 Multiple types of atomizers, mist chambers, and torch tubes are available, which can meet different injection requirements such as organic, high salt, high sensitivity, and HF acid resistance, making it easy to replace and maintain.

1.7 Integrated gas path fully automatic control, using precision mass flow controller to control multiple gas flow rates with an accuracy of 0.01L/min.

1.8 Gas shortage protection function, the instrument automatically shuts down when the gas source is exhausted and emits an alarm sound in real time through a buzzer.

1.9 Flame video monitoring, the instrument is equipped with a highly sensitive flame sensing system and a visual video monitoring camera, which can observe the flame status of the combustion chamber in real time and automatically turn off the RF power supply when the flame is turned off, protecting important components of the instrument.

The 1.10 visualized instrument operation status monitoring module can monitor the operation status of each component of the instrument, determine the cause of faults, and facilitate the normal operation of each component.

2. Plasma system

2.1 Plasma observation method: Vertical rectangular tube.

2.2 Fully digital controlled RF power supply, power range 500-1600W, adjustable continuously for 1W; Power stability: ≤ 0.01%.

2.3 Self excited all solid state RF generator: fast matching, automatic tuning, water-cooled heat dissipation.

2.4 Intelligent attenuation: With automatic attenuation function, it can attenuate samples with concentrations up to 100 times, simplify analysis, and enable samples with high element content and large gradient to be analyzed without manual dilution.

2.5 Frequency: greater than 27.12MHz, frequency stability: ≤ 0.01%.

3. Optical system

3.1 The new generation of stepped gratings and prisms as spectral elements have no moving parts inside and good optical stability.

3.2 Constant temperature optical system, all optical components are sealed in a constant temperature light chamber, and the main unit is designed to be isolated from the light chamber. The precision constant temperature inside the light chamber is 36 ℃± 0.1 ℃, and argon gas is blown.

3.3 Optical path focal length: 440mm, total reflection imaging optical path, quartz prism two-dimensional dispersion system.

3.4 Optical system wavelength range: 165-900nm, full wavelength coverage.

3.5 Wavelength correction: Each time the ignition is triggered, the software automatically uses air element spectral lines such as C, N, Ar to correct the peak position, ensuring the correctness of the analyzed wavelength without the need for wavelength correction solution.

3.6 Purging type optical chamber: For measuring wavelengths below 189nm, argon or nitrogen can be selected for optical path blowing.

3.7 Scattered light: ≤ 2.0mg/L (measured at As 188.980nm in 10000mg/L Ca solution).

3.8 Optical resolution: ≤ 0.007nm (at 200nm).

4. Detection system

4.1 High efficiency semiconductor cooled CCD solid detector with continuous pixels within the wavelength range of the spectrometer, allowing for arbitrary wavelength selection.

4.2 Adopting high-efficiency semiconductor refrigeration (three-stage TEC), the refrigeration temperature can reach -45 ℃, and the start-up time is less than 3 minutes.

4.3 Anti saturation overflow: Design a back leakage anti overflow protection for each pixel to completely eliminate the problem of spectral line saturation overflow.

4.4 Intelligent Integral Design: Synchronized signal background acquisition, while obtaining high-intensity and weak signals at the optimal signal-to-noise ratio, expanding the dynamic range and enabling simultaneous detection of high and low content elements.

4.5 The surface of the detector has no light conversion chemical coating, and the detector will not be damaged or replaced due to coating aging. 4.6 The detection unit shall not be less than one million pixels.

5. Software

5.1 The graphical user interface provides convenient and intuitive software operation, with qualitative, semi quantitative, and quantitative analysis functions.

5.2 With a spectral line library of over 75000 lines, each line can select at least 30 pixel points for measurement, and an open software database.

5.3 It has full spectrum acquisition function, and the software can directly obtain complete full spectrum images to understand the sample spectrum and spectral interference status.

5.4 It has multiple interference correction methods and real-time background subtraction functions, such as external standard method, internal standard method, interference element correction coefficient method (IEC), standard addition method, etc., and various means of data analysis and verification.

5.5 Equipped with a visual instrument operation status monitoring module.

5.6 Equipped with a full-color plasma real-time camera system, which can monitor the plasma flame status through software.

5.7 The software can choose to configure audit tracking function, which can achieve multi-user and multi-level permission settings, and has complete operation log recording. The software test results can be automatically uploaded to the designated computer within the local area network, greatly improving work efficiency.

6. Performance indicators

6.1 Analysis speed: ≥ 50 elements or spectral lines per minute, and the integration time of each measured spectral line is ≥ 10 seconds;

6.2 Sample consumption:<2ml, determine no less than 70 elements;

6.3 Spectral line flexibility: can achieve qualitative, semi quantitative, and quantitative analysis of analytical elements;

6.4 Linear dynamic range: ≥ 106;

6.5 Internal standard correction: The internal standard correction function can achieve simultaneous exposure of internal standard elements and measurement elements;

6.6 Precision: Measure 1ppm or 10ppm multi-element mixed standard solution, and repeat the measurement ten times with RSD ≤ 0.5%;

6.7 Stability: Determine the stability of 1ppm or 10ppm multi-element mixed standard solution, with a long-term stability RSD<1.0%;

6.8 Detection limit: The detection limit of typical elements can be as low as 0.1ug/L.

Article address:https://www.spectrometer.top/pro9/39.html

- Previous: ICP spectrometer

- Next: Inductively Coupled Plasma Emission Spectrometer

Current

location:

Current

location: