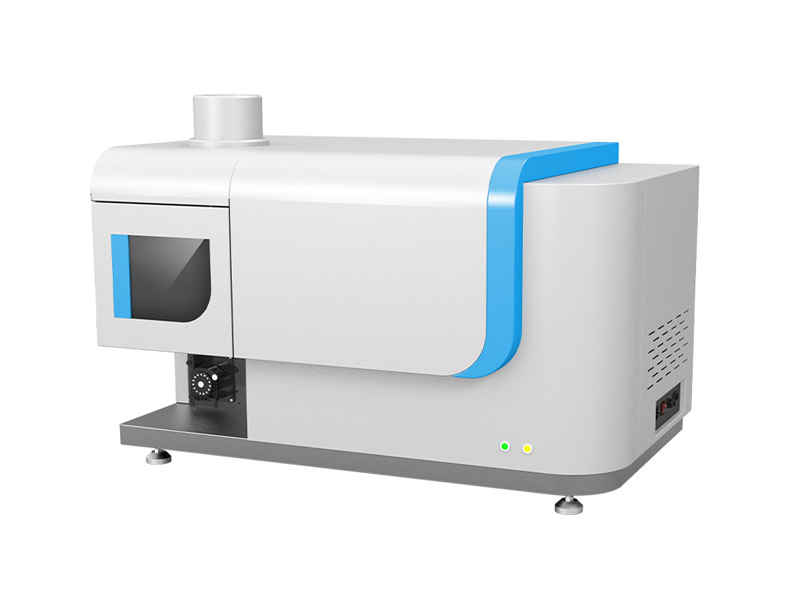

As an important branch of the healthy textile field, the core efficiency of far-infrared functional textiles directly depends on the key physical parameter of far-infrared emissivity. The textile far-infrared emissivity tester is used to accurately measure the far-infrared emissivity of textiles in a specific wavelength range (5 μ m~14 μ m). This instrument simulates the surface temperature of human skin (about 34 ℃), measures the radiation intensity of the sample in the far-infrared band, and compares it with an ideal blackbody to calculate the far-infrared emissivity of the sample. This indicator directly reflects the advantages and disadvantages of the far-infrared function of textiles, and is the core basis for evaluating the quality of functional textiles.

Core technical principles

The core principle of the textile far-infrared emissivity tester is to compare the tested textile with an "ideal reference" - a standard blackbody plate with a known emissivity, in order to calculate its emissivity.

The testing process can be decomposed into the following key steps:

Establish benchmark: The instrument first places a standard blackbody plate with an emissivity of 0.95 or higher on a precision controlled hot plate. The hot plate precisely heats and stabilizes the blackbody plate at (34 ± 0.1) ℃ (close to the average temperature of human skin). At this point, the built-in far-infrared radiation measurement system of the instrument (whose spectral response range accurately covers the most beneficial far-infrared band for the human body, from 5 microns to 14 microns) will measure and record the reference radiation intensity (I ₀) of the blackbody panel at this temperature. Since the emissivity of the blackbody plate is known, this step establishes an absolute scale for measurement.

Sample measurement: Remove the standard blackbody plate and cover the textile sample to be tested on the same hot plate. Under identical conditions (same temperature, same measurement system), wait for thermal equilibrium, and measure the radiation intensity (I) on the surface of the sample.

Calculation and output: According to Kirchhoff's radiation law, at the same temperature, the emissivity of an object is equal to the ratio of its radiation intensity to that of a blackbody. Therefore, the far-infrared emissivity (ε) of the sample is automatically calculated using the formula ε=I/I ₀.

Technical essence: This process cleverly avoids the enormous difficulty of directly measuring the absolute radiation energy on the surface of an object, and instead converts it into a high-precision relative measurement problem, thereby ensuring the accuracy and reliability of the results. The ± 0.1% testing accuracy and ± 0.1 ℃ temperature control accuracy of the instrument are precisely designed to ensure the ultimate precision of this comparison process.

Technical advantages and performance indicators

Based on the above principle, this textile far-infrared emissivity tester has demonstrated its technical advantages in engineering implementation.

1. Measurement accuracy and repeatability

High precision benchmark: Using a standard blackbody plate with an emissivity of 0.95 or higher, it provides an almost ideal reference source for measurement.

Precision temperature control system: The temperature control accuracy of (34 ± 0.1) ℃ is crucial because the radiation intensity of an object is extremely sensitive to its temperature, and even small temperature fluctuations can cause significant deviations in measurement results. Accurate temperature control is the cornerstone of data comparability.

± 0.1% testing accuracy: This indicator ensures excellent consistency of the instrument even in multiple measurements, which is of decisive significance for formula fine-tuning in the research and development process and quality stability monitoring in production.

2. Band positioning and applicability

5-14 μ m spectral response: Strictly aligned with the far-infrared band that has been scientifically proven to have the best physiological effects on the human body, the measurement results are highly correlated with the actual functional claims of the product, avoiding disputes caused by different measurement bands.

3. Standardization and Convenience

Compliant with national standards: Strictly following GB/T 30127 ensures comparability of test results from different laboratories and batches, establishing a unified "language" for the industry.

Moderate hot plate size: a circular surface with a diameter of not less than 60mm, which can meet the sampling requirements of most textiles and ensure the uniformity of the thermal field.

Article address:https://www.spectrometer.top/news/45.html

Current

location:

Current

location: