Product Introduction:

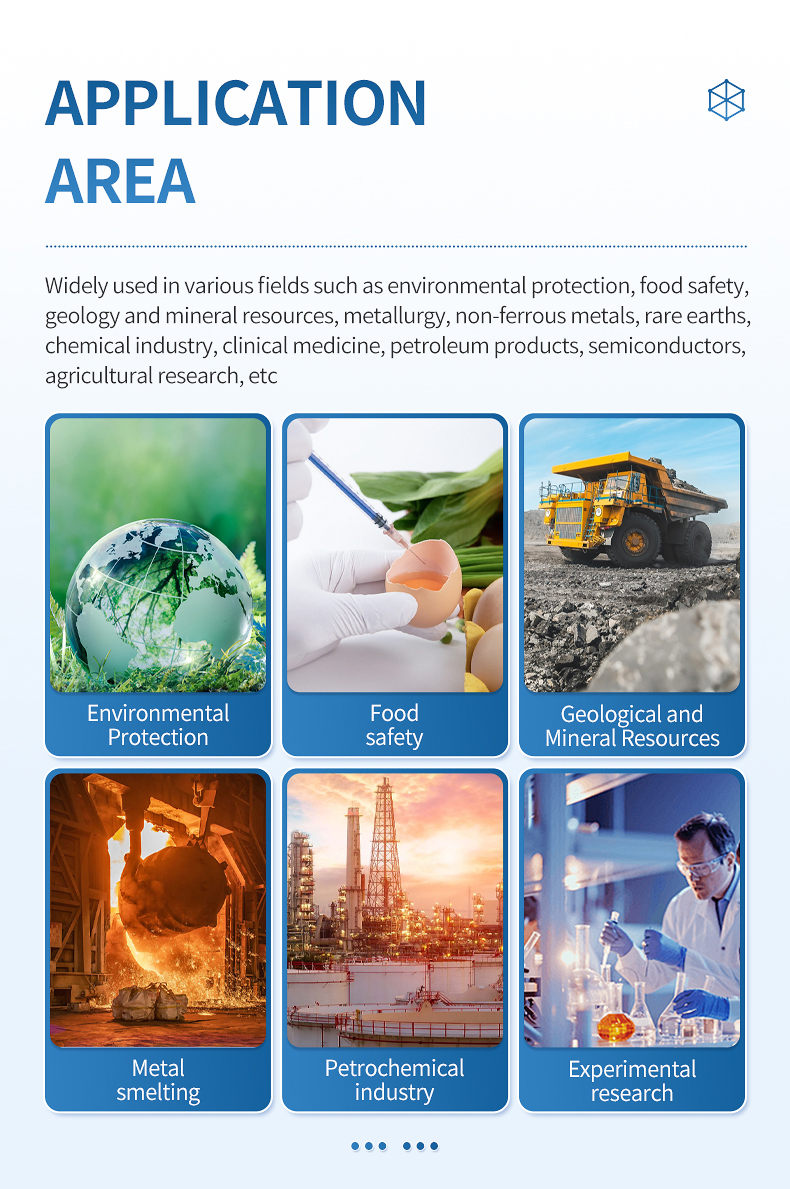

Inductively coupled plasma emission spectrometer, as a professional laboratory analysis instrument, is a new generation product developed by Hengmei Technology Co., Ltd. It has many characteristics such as multiple testing elements, up to 70 types of elements, fast testing speed, and low detection limit. Mainly used in rare earth industry, silicon industry, petrochemical industry, ore analysis, metal smelting, geological research, drug safety, experimental research, environmental detection and other fields.

Inductively coupled plasma emission spectrometer is a trace element composition analysis and testing instrument using high-sensitivity photomultiplier tubes as detectors. It tests nearly 70 types of elements and has a solid-state radio frequency generator and automatic tuning matching technology; Configure a dedicated circulating cooling water system, argon gas conduit, cooling water pipe, and high-sensitivity injection system (high-efficiency atomizer with dual cylinder atomization chamber).

Instrument features:

1. There are many testing elements, and up to 70 types of elements can be tested.

2. Multi element simultaneous testing, testing all elements simultaneously in one injection.

3. The analysis speed is fast, about 5 elements per minute, and the fastest testing speed can reach 10 elements per minute.

4. The detection limit is low, and the vast majority of elements can reach the ppb level.

5. The linear range is wide, up to 5-6 orders of magnitude, allowing for simultaneous testing of high and low content without the need to replace standard curves.

6. Less chemical interference, more accurate test results.

Performance characteristics:

1. Safe and reliable solid-state RF power supply: The RF power supply used in the instrument has small size, high output efficiency, stable output power, and various safety protection functions such as water, gas, and overload, greatly improving the safety of the instrument and reducing its failure rate.

2. High degree of instrument automation: The automation level of the instrument is extremely high, and all operations except for the power switch are completed by software. Intelligent software that can provide real-time feedback and information prompts for various operations.

3. Fully automatic ignition and matching technology: The software can achieve fully automatic one key ignition, and all parameter settings changes are automatically completed. Combined with advanced automatic matching technology, the ignition success rate is high and the operation is simple.

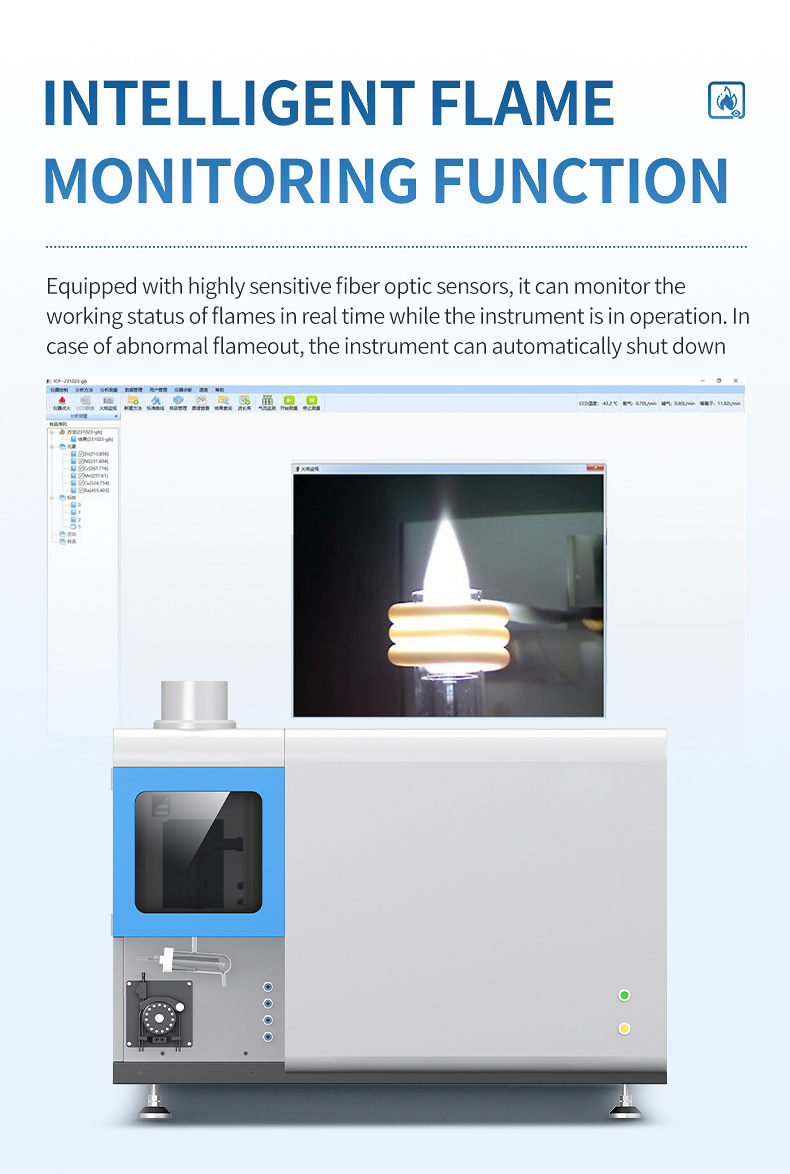

4. Intelligent flame monitoring function: The instrument is equipped with highly sensitive fiber optic sensors, which can monitor flames in real time while the instrument is in operation

In case of abnormal shutdown, the instrument can automatically shut down.

5. High precision airflow control system: The plasma gas, auxiliary gas, and carrier gas used in the instrument are all controlled by high-precision mass flow controllers (MFCs), which have continuously adjustable flow rates and high accuracy in outputting airflow, ensuring the accuracy of test data.

6. Peristaltic pump injection device: The instrument is equipped with a high-precision peristaltic pump with five channels and sixteen rollers, which can ensure the accuracy of injection and prevent liquid accumulation at the same time. The rotational speed of the peristaltic pump is continuously adjustable to meet various testing requirements of customers.

7. Ultra high resolution optical path system: The instrument is equipped with imported 4320 line gratings with ultra-high resolution, combined with unique patented optical path adjustment technology, reducing the resolution of ordinary instruments from about 0.008nm to within 0.005nm. The ultra-high resolution ensures that there is no mutual interference between test elements.

8. High precision constant temperature system: The entire optical path of the instrument is protected by a precision constant temperature system, and the temperature control can be set in real time according to the actual environmental temperature of the customer's laboratory, without the need for long-term continuous adjustment. The temperature control accuracy is ≤± 0.1 ℃, and the precision constant temperature system ensures the stability of the optical path, resulting in more stable test data.

9. Highly sensitive detector: The instrument is equipped with a highly sensitive imported photomultiplier tube (PMT) as the detector, which can automatically set the optimal test parameters for different elements to achieve the best detection state and provide the most accurate test results. No need for refrigeration, no need for blowing, long service life.

10. Ultra low operating cost: When the instrument is not in operation, the power supply, cooling water tank, and gas are all turned off without incurring any costs. The instrument can be turned on and used immediately without the need for prolonged preheating of the optical path. Using argon with a purity of 99.99% is sufficient, eliminating the need for high-purity argon at 99.999%, resulting in cost savings of at least one-third.

11. Automatic adjustment of observation position: The instrument adopts a two-dimensional mobile platform design, which can adjust the position of the torch tube in real time through software and provide feedback

Find the optimal observation position based on the signal value to obtain the strongest sensitivity and achieve the best testing results.

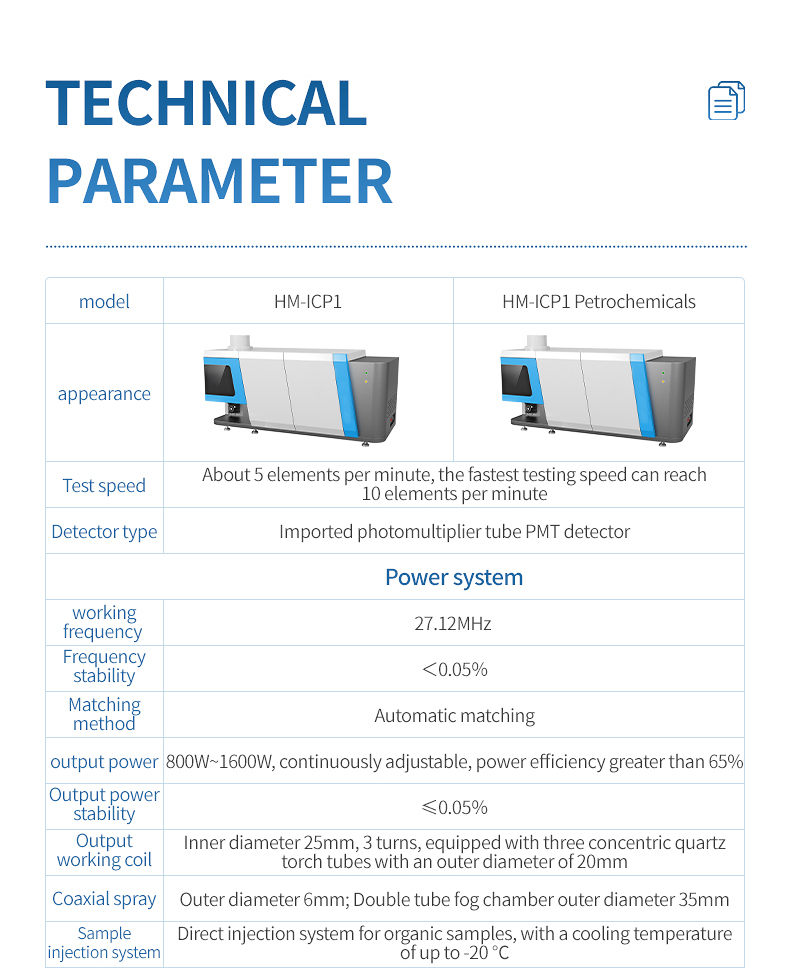

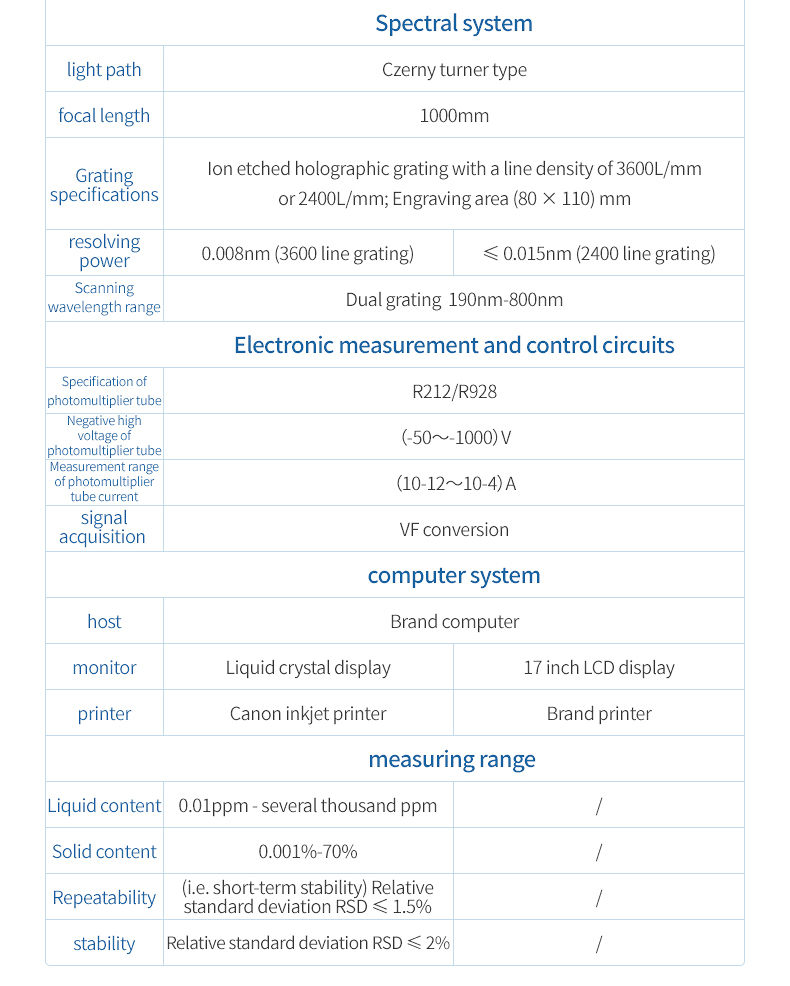

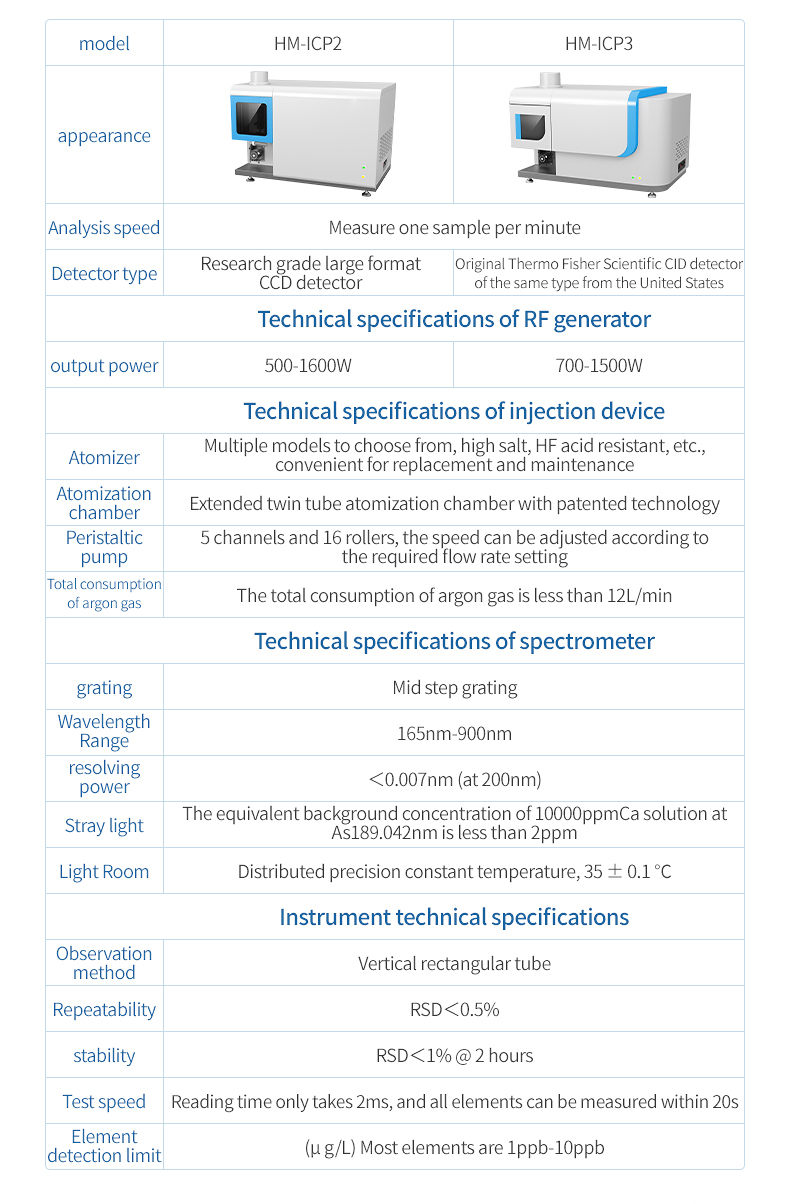

Technical parameters:

1. Power system

Operating frequency: 27.12MHz

Frequency stability:<0.05%

Matching method: automatic matching

Output power: 800W~1600W, continuously adjustable, power efficiency greater than 65%

Output power stability: ≤ 0.05%

Output working coil with an inner diameter of 25mm and 3 turns, equipped with three concentric quartz torch tubes with an outer diameter of 20mm

The outer diameter of coaxial spray is 6mm; the outer diameter of double barrel fog chamber is 35mm

2. Spectral system

Optical path: Czerny turner type

Focal length: 1000mm

Grating specifications: ion etched holographic grating, with a line density of 3600L/mm or 2400L/mm; Engraving area (80 × 110) mm

Resolution: 0.008nm (3600 line grating)

Scanning wavelength range: 3600 line grating: (190-500) nm

3. Detection system

Photomultiplier Tube Specification: R212/R928 Photomultiplier Tube Negative High Voltage: (-50~-1000) V

Measurement range of photomultiplier tube current: (10-12~10-4) A

Signal acquisition: VF conversion

4. Computer System

Host: Brand computer

Display: LCD monitor

Printer: Canon inkjet printer

5. Technical specifications of the whole machine

Scanning wavelength range: 190nm to 500nm (3600L/mm grating)

6. Measurement range

a. Liquid content: 0.01ppm - several thousand ppm

b. Solid content: 0.001% - ---70%

Repeatability: (i.e. short-term stability) relative standard deviation RSD ≤ 1.5%

Stability: Relative standard deviation RSD ≤ 2%

Test speed: 5-10 elements per minute

Article address:https://www.spectrometer.top/pro9/23.html

- Previous: no more

- Next: Atomic Emission Spectrometer

Current

location:

Current

location: