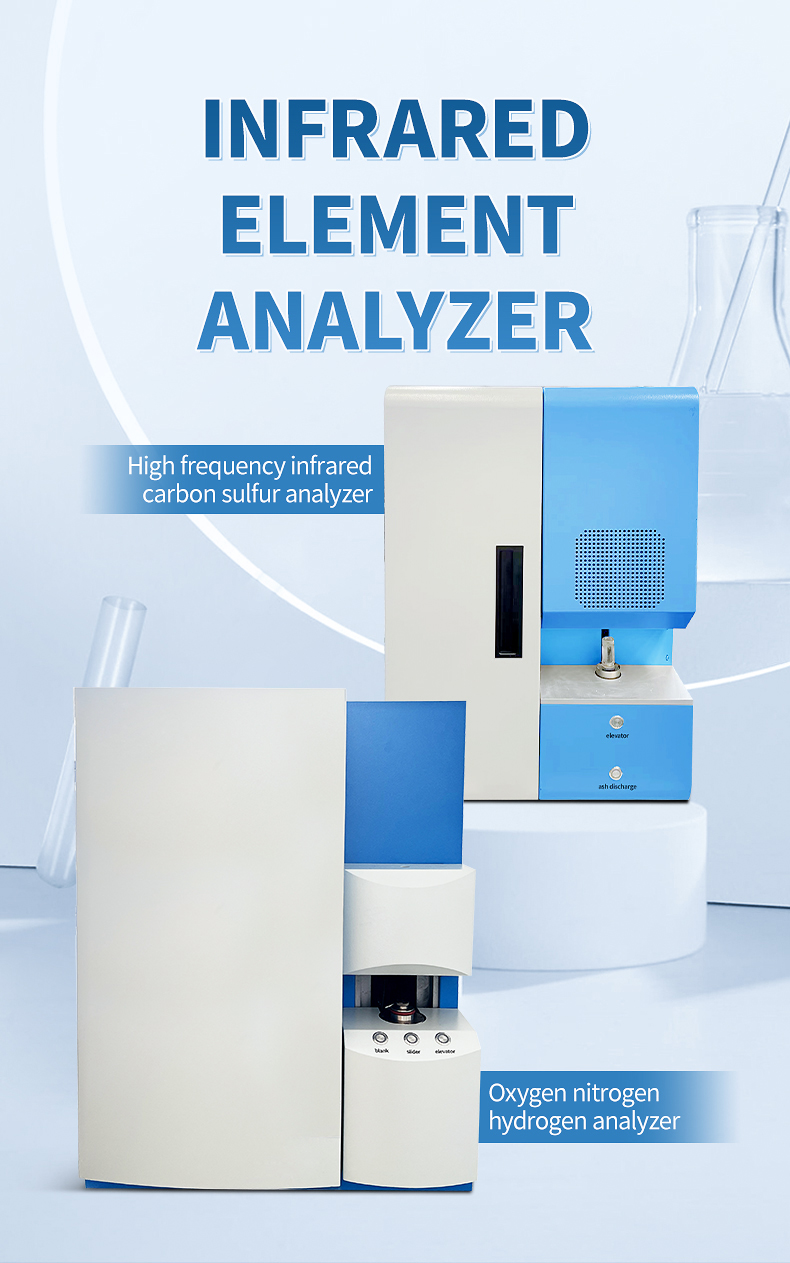

Instrument Introduction

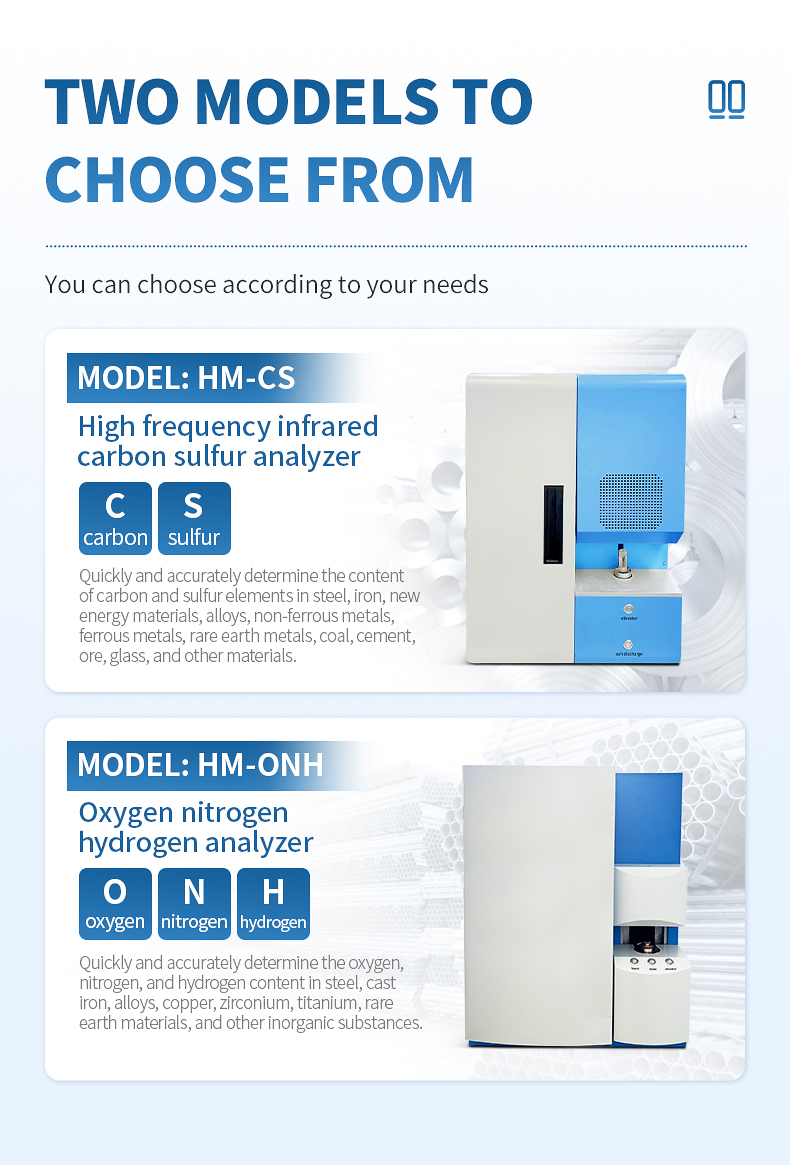

High frequency infrared carbon sulfur analyzer can quickly and accurately determine the content of carbon and sulfur elements in steel, iron, new energy materials, alloys, non-ferrous metals, ferrous metals, rare earth metals, coal, cement, ore, glass and other materials.

Instrument composition

The high-frequency infrared carbon sulfur analyzer consists of a high-precision electronic balance, a high-precision high-frequency furnace module, a specially customized professional industrial computer, and a printer.

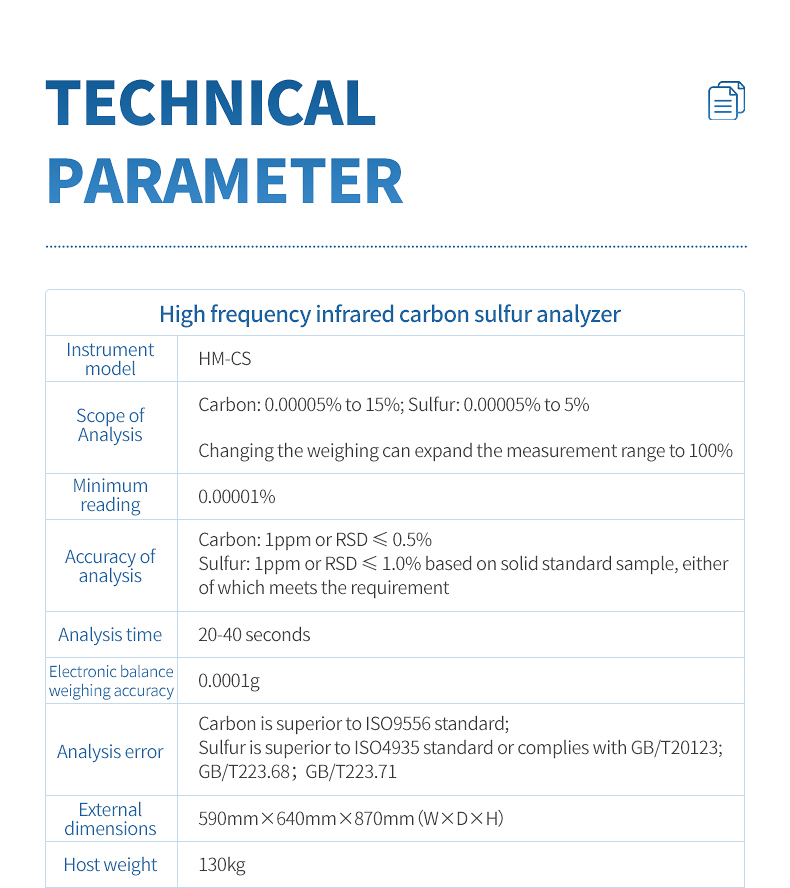

TECHNICAL INDEX

1. Analysis scope:

Carbon: 0.00005% to 15%

Sulfur: 0.00005% to 5%

Changing the weighing can expand the measurement range to 100%

2. Minimum reading: 0.00001%

3. Analysis accuracy:

Carbon: 1ppm or RSD ≤ 0.5%

Sulfur: 1ppm or RSD ≤ 1.0% based on solid standard sample, either of which meets the requirement

4. Analysis time: 20-40 seconds

5. Electronic balance weighing accuracy: 0.0001g

6. Analysis error:

Carbon is superior to ISO9556 standard; Sulfur is superior to ISO4935 standard or complies with GB/T20123;

GB/T223.68; GB/T223.71

7. Host dimensions: W590mmxD640mmxH870mm

8. Host weight: 130kg

Instrument characteristics

1. By using low-noise, high-sensitivity pyroelectric infrared sensors and testing selected carbon dioxide and sulfur dioxide filters, the accuracy of high carbon and low-carbon material analysis is guaranteed. Combined with programmed heating, the impact of instrument background interference on analysis results is effectively reduced.

2. Shielding devices have been added to the signal and power lines, and anti electromagnetic wave leakage devices have been installed on the infrared analysis host, high-frequency oscillation system, and high-voltage section.

3. Advanced and reasonable gas path design, using digital pressure control system and high-precision flow control to stabilize and analyze flow, makes the stability performance of analysis data more excellent.

4. Automatic back blowing and ash removal system, automatic cleaning furnace head system, and optional automatic dust collection function can effectively reduce the impact of dust on carbon and sulfur element analysis.

5. Add an efficient physical dehydration device to the traditional analytical gas path to improve the analysis effect of crystal water on sulfur during the combustion of special samples.

6. The infrared analysis cell adopts high-precision isothermal electron thermal equilibrium technology, effectively improving the repeatability, reproducibility, and reproducibility of sample analysis data.

7. The unique full range linear calibration technology, combined with weight linear compensation, pressure, flow rate, temperature compensation, etc., ensures the analysis accuracy of unknown samples from low to high content within the full range.

8. The optimized design adopts thermally conductive air-cooled ceramic power tubes to improve the heat dissipation effect of the power tubes, the stability of high-frequency induction heating, and the consistency of sample melting.

9. It is the only manufacturer in China that can simultaneously develop and produce specialized consumables for instrument manufacturing and analysis. It can integrate excellent consumable performance into the quality of instruments, highlighting the advantages of instrument analysis application technology.

Article address:https://www.spectrometer.top/pro8/22.html

- Previous: no more

- Next: no more

Current

location:

Current

location: