In modern analytical laboratories, traditional methods often fall short in accurately determining trace elements in complex samples. At this point, ICP spectrometer has become an indispensable core tool with its unique advantages. So, how does it work and why does it gain widespread trust?

Core technical principle: element "fingerprint" recognition under high temperature excitation

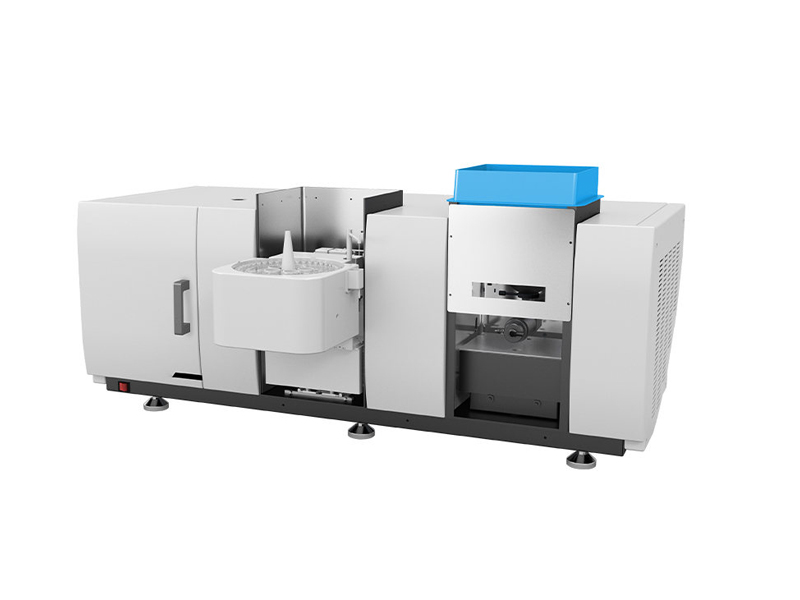

Its core lies in the inductively coupled plasma (ICP) source. Argon gas ionizes under high-frequency electromagnetic fields, forming a plasma torch with a temperature of up to 10000K. The sample solution is atomized and sent into it, undergoing processes of solvent removal, vaporization, dissociation, and excitation in an instant. When the outer electrons of atoms or ions in the sample absorb energy and transition to a high-energy state, and then return to the ground state, they release characteristic spectra of specific wavelengths. The instrument separates these spectra through a precision grating spectroscopic system and captures them with a high-sensitivity photomultiplier tube (PMT) detector. Each element has its unique "fingerprint" spectral lines, and by identifying and measuring the intensity of these spectral lines, qualitative and quantitative analysis of multiple elements in the sample can be achieved.

Significant technological advantages, solving industry pain points

Simultaneous analysis of multiple elements, efficiency leap: With one injection, up to 70 types of elements (such as rare earth systems, heavy metals, etc.) can be simultaneously determined, and 5-10 elements can be detected per minute, completely solving the efficiency bottleneck of traditional methods (such as AAS) that require element by element analysis.

Ultra low detection limit, insight into the trace world: The detection limit of the vast majority of elements can reach ppb level (one billionth), meeting the stringent requirements for trace and ultra trace components in environmental pollutant monitoring, high-purity material analysis, etc.

Wide dynamic range, high and low content all at once: The linear range is as wide as 5-6 orders of magnitude, and there is no need to dilute or replace the curve. It can accurately determine the main components and trace impurities in the sample at the same time, simplifying the process.

Strong anti-interference ability and accurate and reliable results: The high-temperature plasma environment effectively overcomes chemical interference, combined with ultra-high resolution optical paths (such as 4320 line grating, resolution<0.005nm), greatly reducing spectral line overlap interference and ensuring data accuracy.Automation and intelligence, convenient and stable operation: fully automatic ignition, intelligent flame monitoring, automatic optimization of two-dimensional observation position, precise constant temperature optical path (temperature control accuracy ≤± 0.1 ℃) and software control, significantly reducing operational difficulty and human error, improving instrument stability and reproducibility.

Cost optimization: Ready to use design reduces preheating energy consumption, using 99.99% pure argon gas for stable operation (no need for 99.999% high-purity argon gas), significantly reducing long-term operating costs.

Wide range of application areas and solutions

Environmental monitoring: Accurately measure heavy metals (such as As, Cd, Hg, Pb) and toxic elements in water, soil, and solid waste, providing data support for environmental governance. (Pain point solution: To cope with increasingly strict environmental standards and achieve high-throughput and high-sensitivity detection of multiple elements)

Geology, Mineral Resources, and Metallurgy: Quickly analyze the composition of primary, secondary, and trace elements in ores, concentrates, metals, and alloys to guide mineral exploration and optimize smelting processes. (Pain point solution: Simultaneous analysis of multiple elements in complex matrices to improve resource assessment and quality control efficiency)

Petrochemical industry: Monitor the metal content in crude oil, lubricants, and catalysts, evaluate product performance and equipment wear. (Pain point solution: Stable detection of trace metals in high organic matrix samples such as oil products)

Food and drug safety: Detect trace harmful elements (such as Pb, As, Cd, Hg) and nutrients in drug raw materials, finished products, and food to ensure safety and compliance. (Pain point solution: Meet the strict detection requirements of regulations for trace pollutant limits)

Materials Science: Analyze impurity elements in high-purity metals, semiconductor materials, and rare earth functional materials to support the development and quality control of new materials. (Pain point solution: precise determination of trace impurities in high-purity materials)

Application case highlights

A rare earth separation enterprise: using ICP spectrometer to perform real-time multi-element (La Lu, Y, Sc, etc.) analysis on the rare earth extraction process liquid, accurately controlling the separation process, increasing the qualification rate of high-purity rare earth products by 15%, and significantly reducing rework costs.

Provincial Environmental Monitoring Station: Utilizing its high-throughput advantage, it completes the screening of 8 key monitored heavy metals (Cu, Zn, Cr, Ni, As, Cd, Hg, Pb) in nearly 100 surface water samples in a single day, with detection limits far below the national standard limits, efficiently supporting water quality assessment and pollution warning.

Pharmaceutical company QC laboratory: Strictly detect heavy metal and harmful element residues in traditional Chinese medicine decoction pieces to ensure compliance with the limit standards of the Chinese Pharmacopoeia. Batch testing time is reduced by 60% compared to traditional methods, effectively ensuring patient medication safety.

Precision detection drives industrial upgrading

As the "elemental scout" of modern analytical laboratories, ICP spectrometers continuously safeguard environmental safety, resource utilization, industrial production, and human health with their efficient, accurate, and comprehensive multi-element analysis capabilities. Choosing an ICP spectrometer with excellent performance, stability, and reliability is the key to enhancing the core competitiveness of the laboratory.

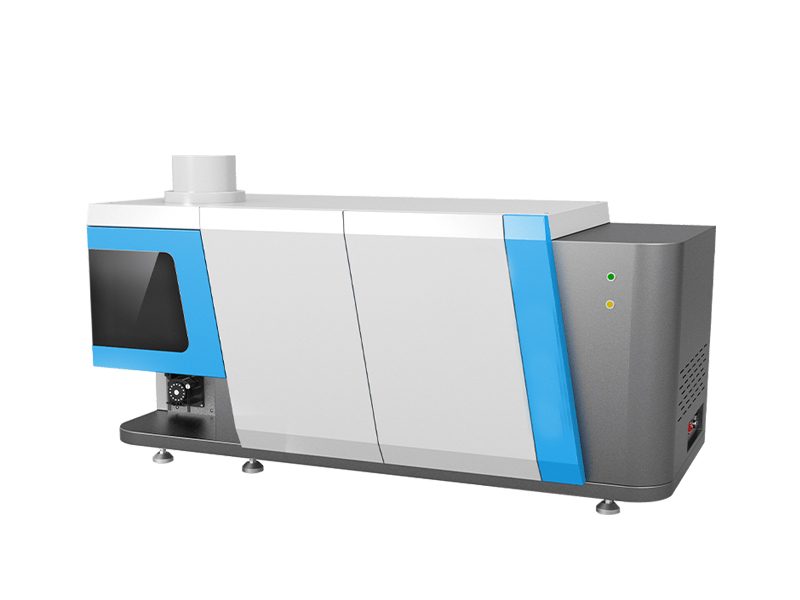

It is worth noting that the new generation ICP spectrometer launched by Shandong Hengmei Electronic Technology Co., Ltd. deeply integrates the core technological advantages mentioned above. It adopts solid-state RF power supply to ensure safety and stability, high-precision constant temperature optical path and imported high-sensitivity PMT to ensure accurate data, unique two-dimensional observation position automatic adjustment technology to optimize sensitivity, and significantly reduce argon gas consumption and operating costs, providing powerful multi-element analysis solutions for users in various industries. Hengmei Technology is committed to using innovative instruments to help customers understand the world of elements, drive quality improvement and scientific development.

Article address:https://www.spectrometer.top/news/24.html

Current

location:

Current

location: