Application solutions in the field of jewelry testing

Identification of gemstone composition

Non destructive testing: By irradiating the surface of a gemstone with a laser (without touching or damaging the sample), Raman spectra can be directly obtained to analyze its molecular vibration characteristics and quickly identify the type of gemstone (such as diamond, jadeite, ruby, etc.).

Authenticity identification: detecting differences in characteristic peaks in synthetic gemstones (such as CVD cultivated diamonds), or identifying Raman signals of fillers (such as epoxy resin in jadeite B).

Package analysis: Penetrating packaging materials such as glass and plastic to detect the composition of the package inside the gemstone, assisting in determining the origin and processing technology.

Precious metal and jade detection

Purity analysis: Quantitatively analyze the purity of precious metals (such as gold and platinum) through the intensity of spectral characteristic peaks.

Jade classification: Distinguish natural jade from imitations that have been dyed or glued, such as determining whether the jade has been optimized based on the smoothness of the spectral baseline.

On site rapid screening

Support detection through transparent containers such as glass and plastic bags, suitable for real-time screening in jewelry markets, auction houses, and other scenarios.

Application solutions in the field of industrial material analysis

Material composition characterization

Inorganic materials: Analyze the composition of ceramics, glass, minerals, etc., such as detecting the crystal structure or defects in industrial ceramics.

Polymer materials: Identify the molecular chain structure of polymers (such as plastics and rubber), detect additives or pollutants.

Industrial product quality control

Semiconductor materials: detecting surface stress and impurity distribution of silicon wafers and nanomaterials.

Coatings and coatings: Analyze the thickness and uniformity of metal coatings, and evaluate their anti-corrosion performance.

Dangerous goods testing

Identify the molecular characteristics of hazardous chemicals (such as flammable and explosive materials) in industrial environments to ensure production safety.

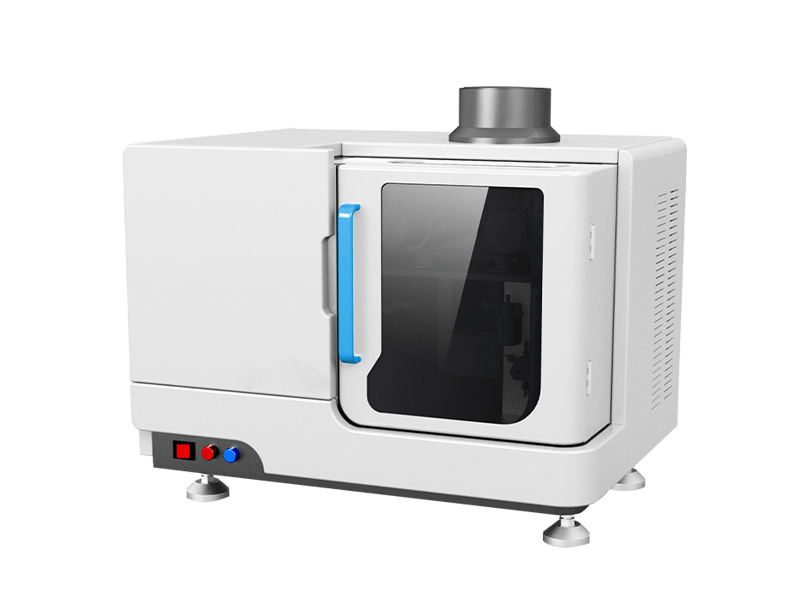

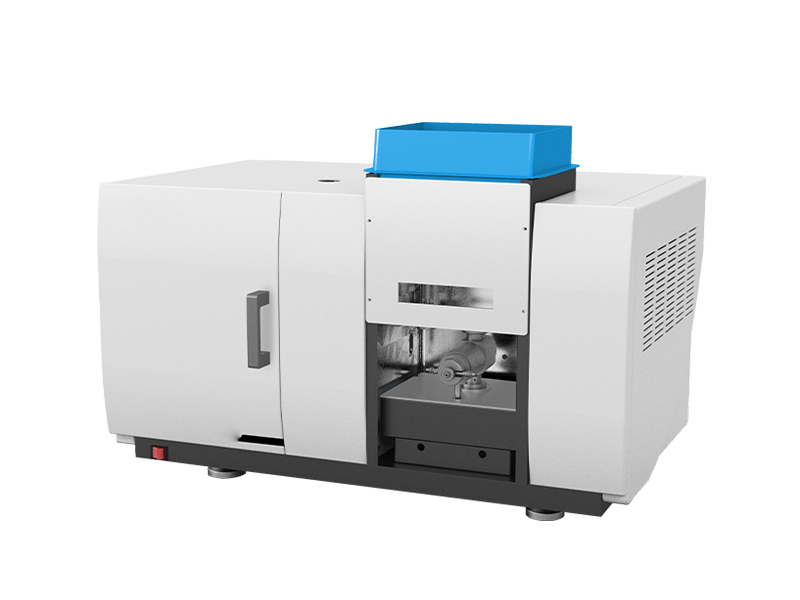

The core advantages of Hengmei Raman spectrometer

Technical performance

High resolution: The spectral resolution reaches 6-9 cm ⁻¹, which can accurately distinguish similar substances (such as natural and synthetic diamonds).

Wide spectral range: covering 200-3300 cm ⁻¹, supporting analysis of organic, inorganic, and composite materials.

Intelligent spectral analysis algorithm: Built in cloud based spectral library, supporting automatic matching and unknown object identification, reducing manual interpretation errors.

Convenience of operation

One click detection: It only takes a few seconds from startup to output results, suitable for rapid on-site screening.

Portable design: weighs only 500g-4kg, supports IP66 protection level, and is suitable for harsh industrial environments.

Scalability

Support multi module integration (such as SERS enhancement technology) to improve the sensitivity of trace substance detection to the ppm level.

Hengmei portable Raman spectrometer provides authenticity identification and quality evaluation for jewelry identification through non-contact, high-precision, and intelligent technological advantages, while achieving rapid component screening and quality control for industrial material analysis. Its flexible application scenarios and cloud data management capabilities further enhance detection efficiency and industry compliance.

Article address:https://www.spectrometer.top/solu/32.html

Current

location:

Current

location: